What is Boundary Scan?

JTAG/Boundary Scan is probably the most ingenious test process, which like ICT, tests within the circuit and detects structural fault locations by setting thousands of test points – even under BGAs – with only four test bus lines.

Boundary Scan essentially means “testing at the periphery (boundaries) of a circuit”.

In addition to the core logic and the test points, an IC (Integrated Circuit) also features some test control logic. The test points are integrated between the core logic and the physical pins of the IC. This special IC architecture and the test bus connections among each chip are preconditions for the use of Boundary Scan. If they are met the prediction of Boundary Scan is possible

- Test particular components

- Test the connections among the ICs on the board

- Test the function of complete boards under operating conditions

Not all components on the board have to be testable in order to use the Boundary Scan philosophy. Even if only one component meets the Boundary Scan requirement, Boundary Scan can be used for certain test applications. Please ask us to run a testability analysis on your boards to show that there are thousands of components that can be tested with Boundary Scan.

Unlike other test access methodologies, Boundary Scan can be utilised from the beginning to the end of the production of a PCB for the following applications:

- Testing

- Design verification

- In-system programming

- Debugging

- Emulation

Advantages of the JTAG/Boundary Scan technology:

- Usable throughout the entire product life cycle

- No mechanical access necessary – while still offering very high test coverage

- Accelerates development of new products – reduced time to market

- Test program generation in a short time – fast turnaround, e.g. for design changes

- Improved product quality by simultaneous testing and programming within one program sequence

Cost savings with the JTAG/Boundary Scan technology:

- Low initial investment and cost of maintenance compared to other test technologies

- No storage costs

- Minimal running costs

- Fast return on investment

Decide for the JTAG/Boundary Scan technology leader!

• Most experienced – GOEPEL electronic is the JTAG/Boundary Scan pioneer and highly reputed vendor since 1991

• Global presence – Five subsidiaries worldwide and a network of more than 350 sales and support experts

• Innovation – Continuous market introductions of numerous awarded JTAG/Boundary Scan products

• Versatility – Biggest portfolio of more than 250 products for your individual test solution

• Market leader – Over 7,000 JTAG/Boundary Scan system installations

• Flexibility – Integration of JTAG/Boundary Scan in existing systems of all ATE vendors

(Drop down to be provided on the left, just below Goepel, which must includes; Software, Hardware, LowCost Package, Integration to ATE systems)

(Under Software)

SOFTWARE:

Software that sets Quality Standards :

The key for successfully utilising JTAG/Boundary Scan is determined by the quality of the applied software – today more than ever. Grown within the innovations across nearly two decades, SYSTEM CASCON™ is the most utilised JTAG/Boundary Scan software platform worldwide. More than 1,000 design and test engineers, quality managers, service technicians and system diagnosticians use this unique integrated software environment every day.

Today, SYSTEM CASCON™ is available in its fourth generation and is the only JTAG/Boundary Scan software that can claim the status of an open, graphical JTAG/Boundary Scan operating system.

Its architecture thoroughly implements GÖPEL electronic’s philosophy of Extended JTAG/Boundary Scan, eclipsing other solutions in regard of test coverage and system functionality by combining various test, programming and emulation methods with native JTAG/Boundary Scan procedures.

Features that make the Difference to other JTAG/Boundary Scan Software Solutions

| <tools.png> Scalable high-performance platform with more than 40 integrated tools, central project data base and intuitive user interface |

| <bulb.png> Simple, fast and goal-oriented project development by intelligent tools and automated system processes |

| <shield.png> Integrated safety functions avoid hardware damaging scan vectors and guarantee safe test programs |

| <eye.png> Interactive Boundary Scan visualisation on layout, schematic and logic level for graphical analysing and debugging |

| <penknife.png> Support of test and programming strategies for internal and external instrumentations beyond Boundary Scan |

| <coverage.png> Extended test coverage and precise fault diagnostic by complete inclusion of non-Boundary Scan circuits |

Its architecture thoroughly implements GÖPEL electronic’s philosophy of Extended JTAG/Boundary Scan, eclipsing other solutions in regard of test coverage and system functionality by combining various test, programming and emulation methods with native JTAG/Boundary Scan procedures.

The completely integrated architecture of SYSTEM CASCON™ provides the flexibility needed to adapt the software configuration to completely different target applications and environments. In this regard, so-called Enable Codes are used as keys to activate or deactivate specific tools and modules of the system.

For the user this approach provides enormous benefits over multi-package solutions since the software configuration can be changed easily and quickly. The handling of updates and upgrades is extremely simple, and problems due to incompatible tools are prevented. Software packages designed for laboratory, production, and field service are available in various performance classes (Editions) as Development Stations (DS) and Test/Execution Stations (TS/ES).

Pure Insystem Programming (ISP) applications can be realised with [CASCON POLARIS™] Editions, while [CASCON GALAXY®] supports both ISP and test procedures. The extensive CASCON Application Programming Interface (CAPI) enables powerful integrations. Floating Licenses provide extreme efficiency with Multi-Seat and Multi-Tooling capabilities.

Fusion of JTAG Emulation and Boundary Scan

![]()

VarioTAP is a revolutionary technology for pattern streaming on TAP (Test Access Port) signals compliant with IEEE Std. 1149.1. The technology utilizes on-chip emulation resources accessible in many micro-processors and micro-controllers through a IEEE 1149.1 compatible JTAG Port. The VarioTAP principle was specifically developed for the integrated Boundary Scan software, SYSTEM CASCON™, and enables the complete fusion of Emulation tools with test and In-System-Programming (ISP) applications.

The VarioTAP specific adaptive streaming showcases the dynamic synthesis of Emulation vectors and Boundary Scan vectors, supporting new test strategies such as Interlaced JTAG/Boundary Scan Tests and In-System Emulation Test / ISP.

(Under Hardware)

HARDWARE:

![]()

Just like the software, GOEPEL electronic’s hardware traditionally meets highest quality and performance demands throughout the entire product life cycle.

The available product line of SCANFLEX® is the fourth generation of GOEPEL electronic‘s Boundary Scan hardware solutions. Coupled with intuitive software, they enable applications far exceeding standard Boundary Scan to be quickly realised. The support of external instrumentations plays a key role.

SCANFLEX® redefines Boundary Scan Hardware

| <80MHz.png> Scalable high-performance platform for scan operations of 80 MHz with up to eight parallel independent TAP interfaces |

| <flexible.png> Separately controlled I/O modules with VarioCore® technology for reconfigurable analogue, digital and Mixed-Signal functions |

| <adaptive.png> Best TAP signal transmission quality also over long distances of up to ten metres with full signal delay time compensation |

| <penknife.png> Broad support of a multitude of test, emulation and programming strategies complementing Boundary Scan |

| <modular.png> Freely configurable controller, I/O modules, TAP transceiver and TAP Interface Cards (TIC) enable scalable system configurations |

| <ate-ready.png> Special front-end hardware ensures seamless integration into In-Circuit Testers, Flying Probe Testers, Functional Testers and other ATE |

Boundary Scan Controller overview:

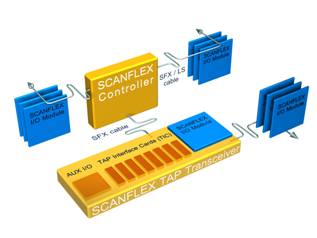

SCANFLEX® hardware systems are controlled through a JTAG/Boundary Scan Controller. This controller is responsible for simultaneous generation and dynamic distribution of serial patterns, parallel patterns, and control sequences, supporting three standard SFX and SFX/LS Interfaces. SCANFLEX® Boundary Scan Controllers from GÖPEL electronic are available in three performance classes (A, B, and C). A main difference between these classes is the implemented Boundary Scan vector memory architecture. B- and C-type controllers feature the patented SPACE™ Architecture for advanced vector handling. The HYSCAN™ feature, available with all SCANFLEX® Controllers, provides a means to synchronize serial JTAG/Boundary Scan vectors and parallel I/O vectors.

As front-end, SCANFLEX® hardware systems use TAP-Transceiver modules. These modules are connected to the controller with the SFX cable (available in 2m/6ft, 5m/15ft, and 10m/33ft lengths). TAP Transceiver modules convert the data coming from the controller into respective operations of the built-in or added-on resources. TAP signals are provided through interchangeable TAP Interface Cards (TIC), allowing a nearly infinite range of front-end adaptations for various signal types, signal conditioning, and integration environments, including custom specific variants. SCANFLEX®TAP Transceivers as well as in rack-mountable housings, and they can be adapted to custom specifications. As a standard configuration, TAP Transceivers also include analog and digital I/O resources, typically at least one SFX I/O slot, and one additional SFX/LS interface, providing ample of resources for extended Boundary Scan test solutions.

The third major component in a SCANFLEX® hardware system is the optional I/O Module. These I/O modules are controlled independently from any other resources in the system through the SFX/LS interface. If the number of required SCANFLEX I/O Modules is very small (only 1 to 2 modules needed) the modules can be plugged directly onto the TAP-Transceiver, eliminating any additional cabling. Alternatively, I/O modules can be put into SCANFLEX Carriers, connected to the Controller or the TAP Transceiver through a SFX/LS cable (0.5m/1.5ft, 1m/3ft, 3m/10ft, or 5m/15ft). SCANFLEX® I/O Modules are used to extend the performance and capabilities of the Boundary Scan system with additional test instruments and programming resources, highly modular and scalable to match any specific test/ISP application. Custom specific modifications of standard modules and development of custom modules are offered through GÖPEL Electronic’s engineering services.

(Under LowCost Package)

LOW COST PACKAGE:

The products of the SCANBOOSTER™ family offers a cost-effective entry solution but with features, which are solely included in the high end systems of our competitors. There is no need of expensive equipment for basic test program generation and interconcection tests.

The SCANBOOSTER™ product family complements the existing spectrum of SCANFLEX® solutions by an independent product range in the lower to mid-range performance area.

Available family members are SCANBOOSTER/USB, SCANBOOSTER/USB-FXT and SCANBOOSTER/PEC. These are JTAG/Boundary Scan controllers on PCI bus, PCI Express and USB2.0 basis, respectively, for JTAG/Boundary Scan test, (C)PLD/FPGA programming and FLASH In-System programming with limited amount of data.

The controller range provides optimal solutions in particular for standard applications with high cost pressure and lower performance requirements.

SCANBOOSTER/USB Designer Studio – Low cost JTAG/Boundary Scan Tester

The SCANBOOSTER/USB Designer Studio is targeted for design, production and services personnel looking for a fast turnaround in terms of application development. The system comes packaged with hardware and software tools that can be used right out of the box.

• Low cost package (Hardware & Software)

• Fast application development cycle

• Powerful software development environment

• Design, production and service applications

• Flexible and expandable with multiple options

• Fully compatible to JTAG/Boundary Scan platform SCANFLEX®

SCANBOOSTER™ Designer Studio is based on the worlwide leading software solution CASCON GALAXY®.

Great advantages:

- the projects has been created with the SCANBOOSTER™ Design Studio can be used in higher expansion stage without any adjustments

- the system can be extended piece-by-piece to handle tasks later on the VarioTAP emulation technology is necessary

It’s the same with the Boundary Scan hardware upgrade. These are also exchangeable among each other by whereby projects are compatible software as well as hardware comprehensive. We don’t restrict you, but we offer you maximum liberty! With the SCANBOOSTER™ Designer Studio you will get unlimited access to the complete service and support network of GOEPEL electronic. So you can access to our over 20 years know how in the field of Boundary Scan within this for your eventually new technology.

Through the unbeatable price performance ratio our Low Cost Boundary Scan system SCANBOOSTER™ Design Studio is the ideal entry into the world of JTAG/Boundary Scan.

(Under Integration in ATE systems)

INTEGRATION IN ATE SYSTEMS:

Stand-alone or Integration?

It doesn’t matter if you decide for stand-alone or an integration, our product portfolio covers it. With the help of our powerful software and hardware, every PC can be transformed into a JTAG/Boundary Scan tester with extended fault coverage.

However, ready-made testers like JULIET include Unit Under Test (UUT) power supply and are preconfigured professional solutions for adapting the UUT.

As far as the analogue circuit parts are concerned, the highest possible fault coverage can be achieved by combining JTAG/Boundary Scan with other methodologies. Numerous integration packages of various performance classes are available for such purposes. Typically, they have been developed in close cooperation with, and are authorised, by the respective ATE vendor.

Increased Test Coverage by Integration on Other Test Methodologies

| <flying-probe.png> Boundary Scan and Flying Probe High flexibility without bed-of-nails for high-mix |

| <funktionstest.png> Boundary Scan and Functional Test High fault coverage also in dynamic domain | |

| <hass-halt.png> Boundary Scan and HASS/HALT Dynamic monitoring for tests in environmental chamber | |

| <in-circuit-test.png> Boundary Scan and In-Circuit Test High throughput with best diagnosis for high-volume | |

| <aoi.png> Boundary Scan and AOI Assembly test and optoelectronic tests | |

| <gang-test.png> Boundary Scan and Gang Test Parallel programming and test of several boards |

Stand-Alone and Integration Solutions – Flexibly defining Production Tests

Nowadays, testing is an important integral part of any quality assurance strategy. But each production environment and every product put different demands on the test equipment. We have consistently taken up this challenge and developed flexible system solutions, which adapt to the production process and can be integrated in existing environments without performance loss. Tests, already developed in the lab, can be directly taken over into the production process for fast New Product Introduction (NPI).

Perfectly equipped by all Means with GOEPEL electronic’s Integration Solutions

| <throughput.png> Shortest test time and high-speed programming of Flash/PLD provide full in-line capability also at very high beat rate |

| <precision.png> Detection, pin accurate diagnosis and layout display of all defects such as shorts or open BGA solder joints within one application |

| <synchronous.png> Complete interaction of Boundary Scan patterns with test vectors of other ATE or AOI systems for highest fault coverage |

| <integration.png> Standard interface control via LabVIEW®,TestStand, C/C++, Basic, Tcl/Tck, Python etc. down to vector level |

| <modular.png> Efficient system utilisation by means of Floating License, fast project transfer through archive files and online fault data tracing |

| <turn-key.png> Availability of custom JTAG/Boundary Scan systems incl. adaptation based on platforms such as PXI or JULIET |

JULIET (JTAG Unlimited Tester) is suitable for the testing of small production batches and prototypes. All electronics are integrated inside the system. The system is based on exchangeable adaptors and can be quickly converted in a few steps to handle different projects.

There are no reviews yet.