|

|

|

|

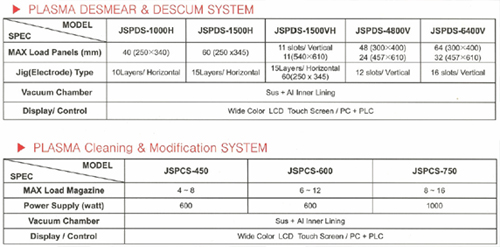

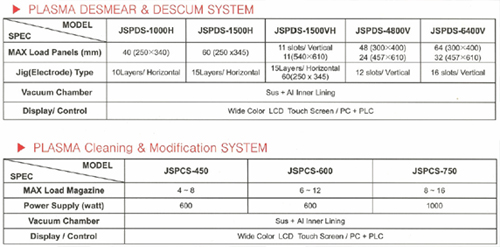

“Ultra thin PCB, VOP Board and HDI board are too thin to be dealt with humans so there is high risk of defect by human mistake or error.

To reduce this kind of mistake due to handling errors, fully automated system is required which can ensure all the process from loading to unloading is automated.

Full Auto plasma system should be designed by considering characteristics of PCB such as size, handling method, line arrangement etc”

|

|

|

|

You must be logged in to post a comment.

PANEL and PATTERN as well as automatic panel loading and collecting devices.For processing thin panels and panels with tiny holes, PAT takes special measures to do the loading and bubble removal in order to improve yields.

This is meant for excellent surface preparation prior to dry film lamination and / or printing processes.

Manufacturer: Hitachi, JapanPWB Co2 Laser Drilling Machine

CNC Printed Wiring Boards Routing Machine

Manufacturer: Kuang Chien Computer Co., Ltd. (Comweb, Taiwan)Model No. TDZ-600AW

Manufacturer: Hakuto Co. Ltd., Japan Automatic Exposure System(Model : HAP5020)

Manufacturer: Hakuto Co. Ltd., JapanLaminator

Manufacturer: Intelicoat Technologies, USA APF Laminator

There are no reviews yet.